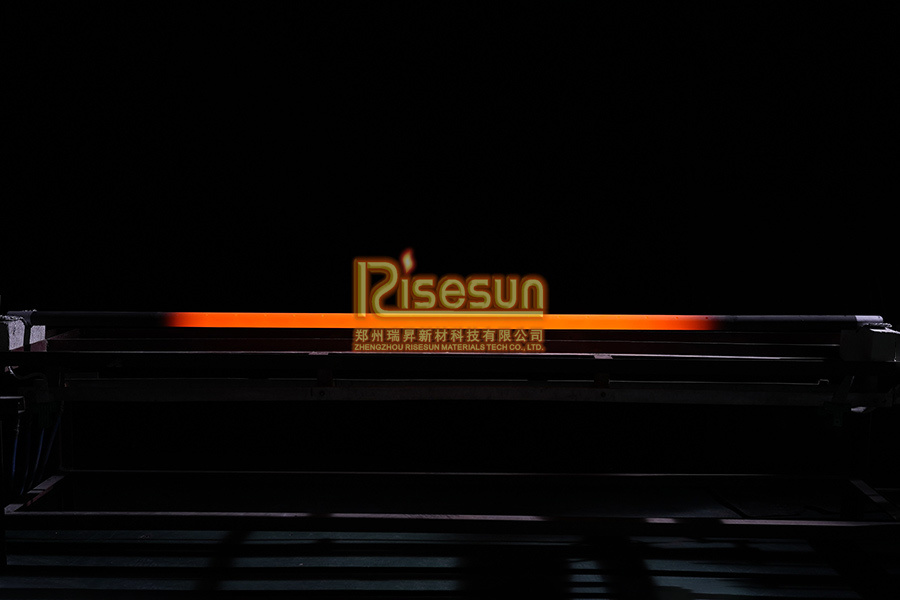

RISESUN MATERIALS

In 2014, Zhengzhou Risesun Materials Tech Co., Ltd. was founded by the team which has more than 30 years of experience in production, technology, management and sales. Risesun has maintained a compound growth rate of over 30% in past years. Our products are sold all over China and exported to dozens of countries, many worldwide well-known manufacturers in various industries included. Risesun has won high praise from head customers in the field of anode and cathode materials of lithium battery and other industries in China, Japan, and South Korea. Risesun has become a well-known brand and leading enterprise of silicon carbide heating elements. The core concept of "professional, quality, integrity, and innovation" is engraved in the hearts of every Risesun person. Risesun has been awarded the National High Tech Enterprise, Environmental Performance A-Class Enterprise, and Risesun is also a member of the National Abrasive and Abrasive Industry Standardization Committee and participated in development of multiple industry standards. Relying on the spirit of efficiency, pragmatism, and technological innovation, we are committed to becoming a global SiC heating element supplier.

The team has over 30 years of experience in production, technology, management and sales.

13,000 square meters new factory

24 patent certificates

Annual production capacity of 500 tons

Risesun Hotbar HD - High-density SiC heating elements

Hotbar SiC heating elements - SiC resistance heating elements

RH type SiC heating elements (equal diameter with higher resistance)

RL type SiC heating elements (equal diameter with lower resistance)

Understanding the Benefits and Applications of MoSi2 Heaters in Electric Heating Solutions

2025-08-29

MoSi2 heaters, or molybdenum disilicide heaters, are an innovative solution in the realm of electric heating devices. Renowned for their ability to operate at high temperatures, they are commonly used in applications requiring reliable and efficient heating. With a maximum operating temperature that can exceed 1800°C (3272°F), MoSi2 heaters have become a preferred choice for many industrial proces

Learn MoreWhy MoSi2 Heating Elements are Essential for Efficient Heating Solutions

2025-08-22

Introduction to MoSi2 Heating Elements In recent years, the demand for efficient heating solutions has surged across multiple industries, making **MoSi2 heating elements** a pivotal component in various applications. These elements, primarily made from **molybdenum disilicide**, are renowned for their exceptional thermal resistance, durability, and ability to operate in high-temperature environm

Learn MoreUnderstanding Kanthal Heating Elements: A Key Component in Electric Heating Devices

2025-08-15

Kanthal heating elements have gained recognition in the electric heating industry due to their durability, efficiency, and versatility. Made primarily from an alloy of iron, chromium, and aluminum, these heating elements are well-suited for a wide range of applications. Understanding their properties and benefits can help professionals in the electric heating sector make informed decisions when se

Learn MoreExploring the Versatility of Erema Heating Elements in Various Applications

2025-08-08

Exploring the Versatility of Erema Heating Elements in Various Applications Table of Contents 1. Introduction to Erema Heating Elements 2. The Technology Behind Erema Heating Elements 3. Diverse Applications of Erema Heating Elements 3.1 Industrial Applications 3.2 Home Appliance Applications 3.3 Medical Equipment Applications 3.4 Automotive Industry Application

Learn More